frontwindslaser

100 Watt Backpack Pulse Laser Cleaning Machine (other types available)

100 Watt Backpack Pulse Laser Cleaning Machine (other types available)

Regular price

$7,899.00 USD

Regular price

$10,299.00 USD

Sale price

$7,899.00 USD

Unit price

per

Tax included.

Couldn't load pickup availability

This pulse cleaning machine irradiates high-frequency and high-energy laser pulses to the surface of the workpiece through laser ablation. The substrate coating layer absorbs the focused laser energy instantly, causing the oil stains, rust spots or coatings on the surface to sublimate or peel off instantly, effectively removing surface attachments or surface coatings and will not harm metal substrates. Moreover, pulsed laser cleaning can be selectively and precisely positioned to clean, only irradiating the part of the workpiece surface you want to remove.

The pulsed laser heat is small and does not substantially heat or cause damage the material surface.

Laser Source

Max 100W

World-famous laser source brand, excellent beam quality, perfect laser characteristics and good pulse shape control ability.

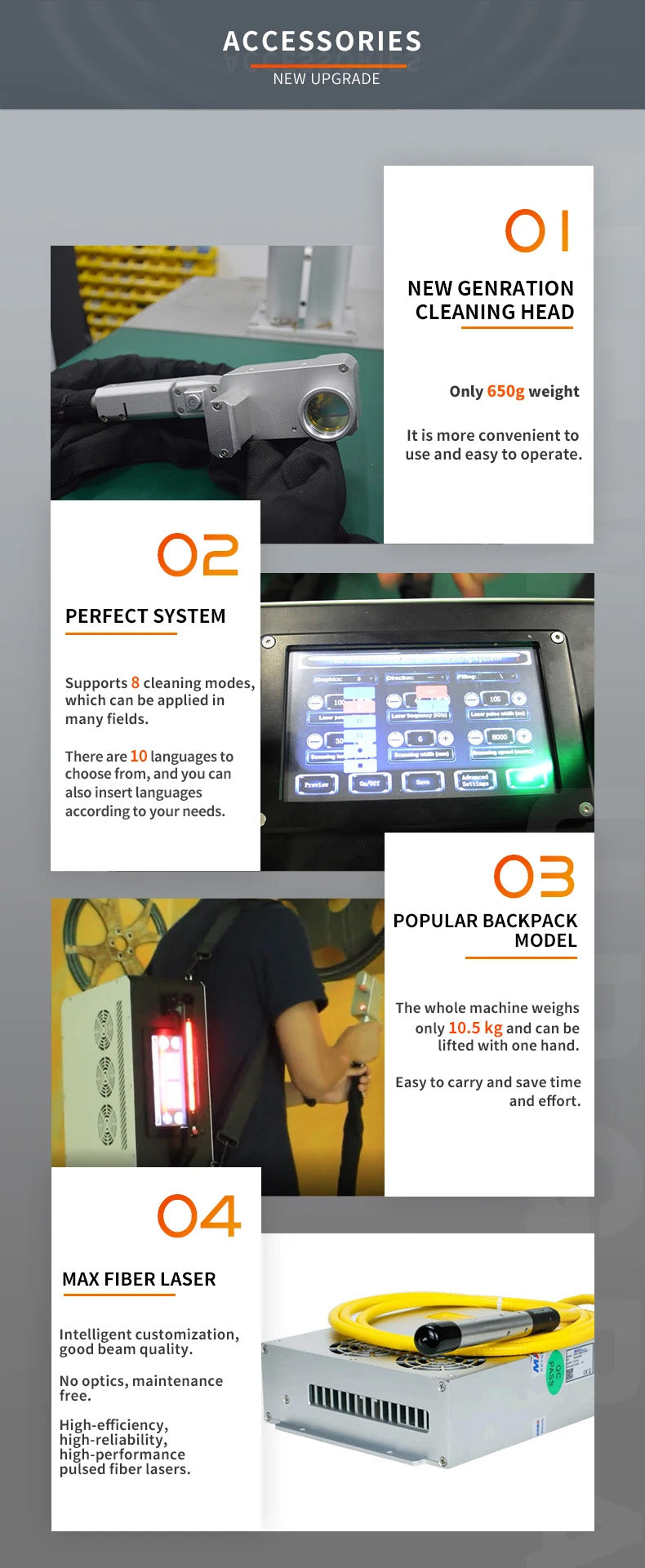

Cleaning Head

Touch Screen System

It has a safety alarm protection system, supports IO\Modbus multiple communication methods, and has more control functions. It also supports customization of LOGO, interface and specific functions and supporting switching between 11 languages.

Easy storage design

Extra space above the machine for fiber optic cables and cleaning heads keeps the machine tidy and protects from dust.

Parameters

Applications

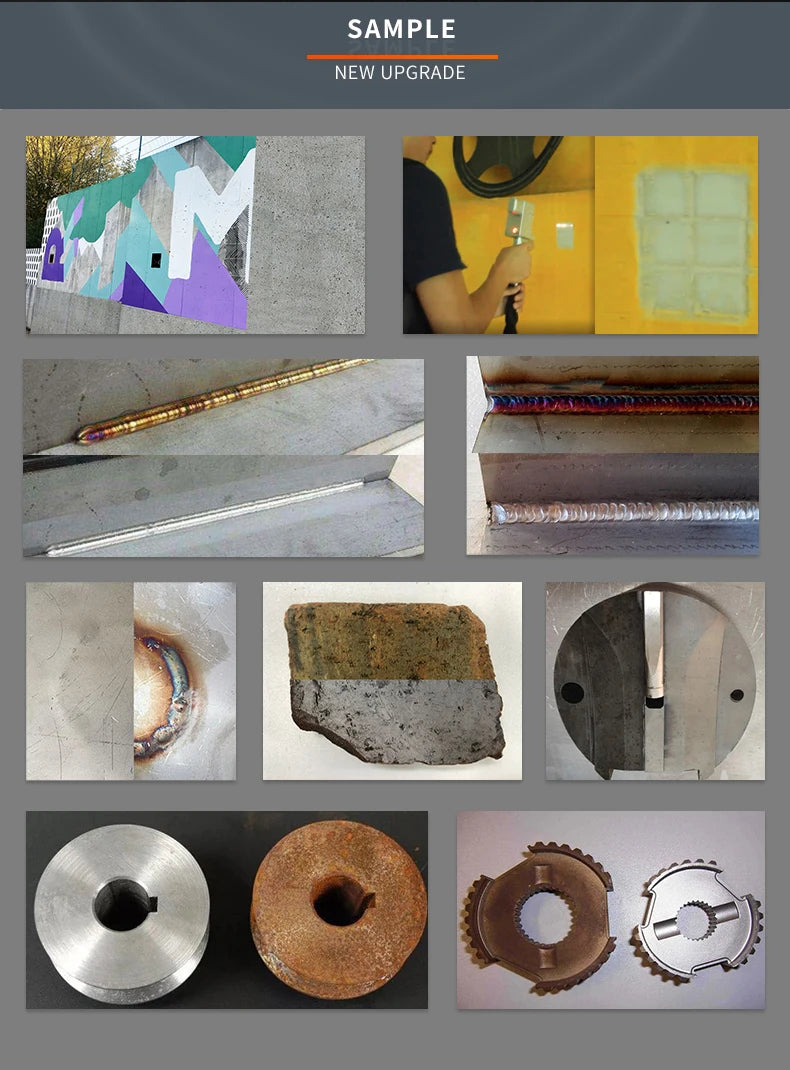

Laser Rust Removal

Fiber laser cleaning removes rust and other corrosion-inhibiting agents with speed and precision, and this, without damaging the base metal. It is often used as a pre-treatment for welding to improve weld quality, or for coatings to prevent paint from failing over time.

Laser Oxide Removal

Laser oxide removal is used to clean metal surfaces before many surface treatments, especially before aluminum welding. It is also used after welding to remove stainless steel oxides.

Laser Paint Removal

Also known as laser coating removal, this method vaporizes paint while leaving the underlying surface intact. It is used to replace part masking, clean painting tools, prepare welding areas, salvage parts with paint defects, and much more.

Laser Surface Texturing

Laser cleaning can remove surface contaminants while leaving a slight texture that improves adhesion. This is useful if you need to prepare surfaces for a subsequent process, such as adhesive bonding or painting.

Laser Cleaning for Welding Applications

Our experts share their laser cleaning results before and after welding. You can see an innovative integration in an automated welding cell, learn the benefits of laser cleaning before and after welding, and obtain laser cleaning speeds.

Laser Cleaning Performance for Metal Contaminants

Our experts compare the speed at which rust, paint, dust, oil and mill scale are typically removed at different power levels. They used our high-power fiber laser to run their tests.

Fiber laser cleaning removes rust and other corrosion-inhibiting agents with speed and precision, and this, without damaging the base metal. It is often used as a pre-treatment for welding to improve weld quality, or for coatings to prevent paint from failing over time.

Laser Oxide Removal

Laser oxide removal is used to clean metal surfaces before many surface treatments, especially before aluminum welding. It is also used after welding to remove stainless steel oxides.

Laser Paint Removal

Also known as laser coating removal, this method vaporizes paint while leaving the underlying surface intact. It is used to replace part masking, clean painting tools, prepare welding areas, salvage parts with paint defects, and much more.

Laser Surface Texturing

Laser cleaning can remove surface contaminants while leaving a slight texture that improves adhesion. This is useful if you need to prepare surfaces for a subsequent process, such as adhesive bonding or painting.

Laser Cleaning for Welding Applications

Our experts share their laser cleaning results before and after welding. You can see an innovative integration in an automated welding cell, learn the benefits of laser cleaning before and after welding, and obtain laser cleaning speeds.

Laser Cleaning Performance for Metal Contaminants

Our experts compare the speed at which rust, paint, dust, oil and mill scale are typically removed at different power levels. They used our high-power fiber laser to run their tests.